Put your parts into production today

-Machining Precisely Since 1993

2024 © Micrometal. All rights reserved.

Designed & Developed by Rudiqs

Shaping the Future with Precision and Efficiency

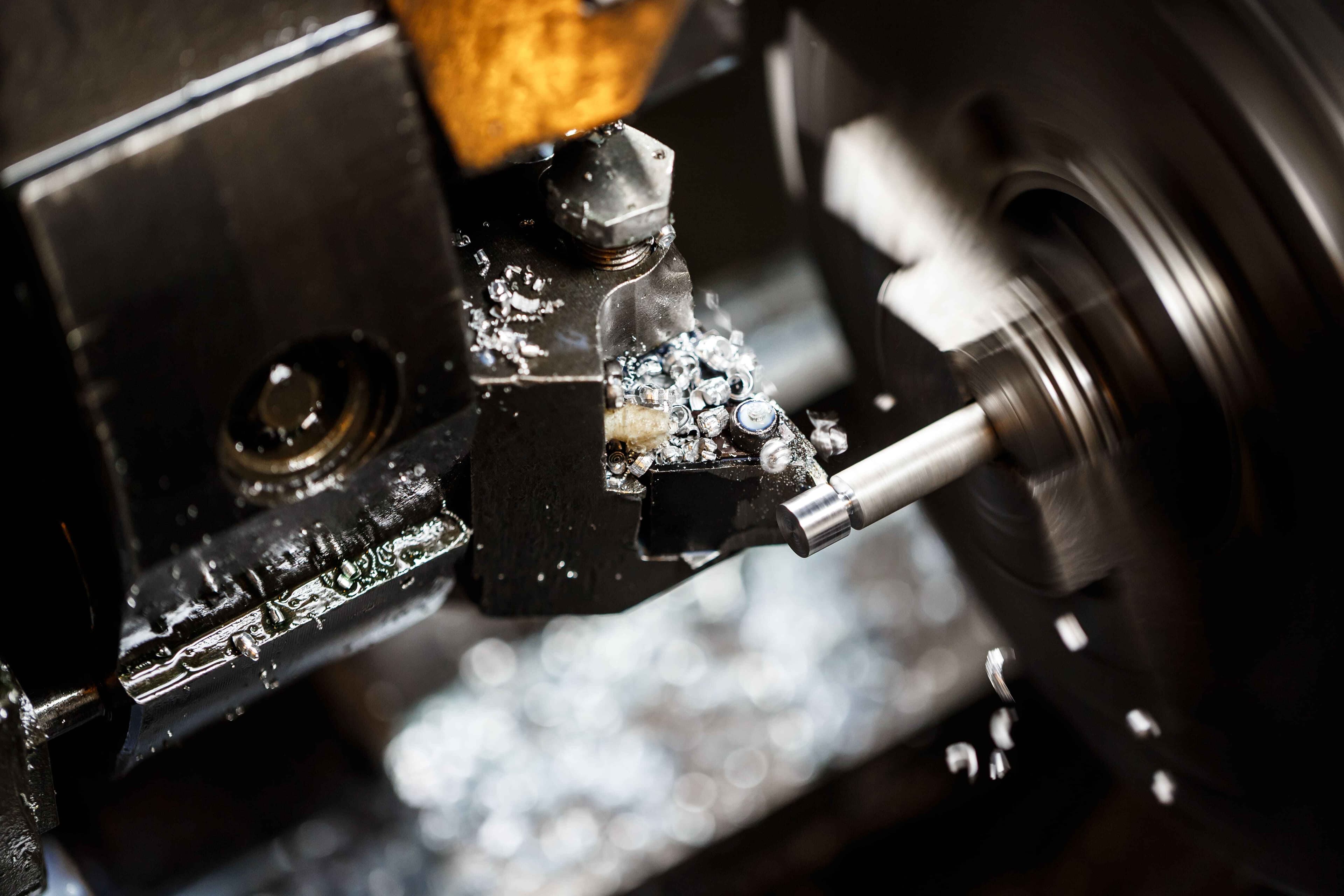

In the intricate world of manufacturing, CNC turning stands as a cornerstone of precision engineering. Leveraging cutting-edge technology and meticulous craftsmanship, CNC turning transforms raw materials into masterpieces of exactitude. With unparalleled accuracy and efficiency, our CNC turning processes unlock new dimensions of possibility, catering to diverse industries with a seamless blend of innovation and expertise. Dive into the realm of precision crafting, where every rotation brings forth a symphony of excellence and perfection

What is CNC Turning?

CNC turning is a manufacturing process that fabricates parts by securing a raw material onto a rotating chuck and shaping it with stationary cutting tools. It is particularly suitable for creating components that exhibit symmetry along their central axis. Compared to milling, turned parts are often produced more quickly and cost-effectively.

Maximum Part Size for CNC Turning

| Part size limitations | Metric units | Imperial units |

|---|---|---|

| Maximum part diameter | 250mm | 9.84in |

| Maximum part length | 650mm | 25in |

| Maximum spindle through-hole | 63mm | 2.48in |

| Maximum speed: 3000RPM,Motor power: 15kva |

Put your parts into production today

-Machining Precisely Since 1993

2024 © Micrometal. All rights reserved.

Designed & Developed by Rudiqs